With TG drives company we created a Control systems of 6-axes industrial robot based on Logimic Edge Control technology. System ensures preparation of trajectories, manual moves, position and speed optimizations and more…

Use case

TG Drives company is producer of TG Motion real-time systems providing control of industrial CNC machines and robots.

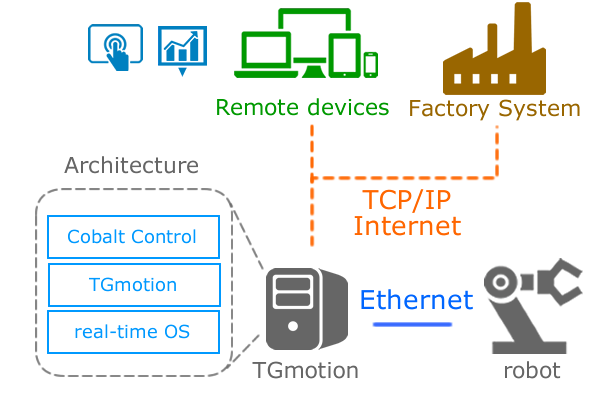

Architecture

System is built on Logimic IoT Control technology and TG Motion real time control system.

TG Motion provides low-level real-time control of industrial machine on control computer.

Logimic IoT Control gateway technology ensures non-real time tasks like visualization, trajectory preparation, optimization and mainly remote access from user devices and cloud.

How it works

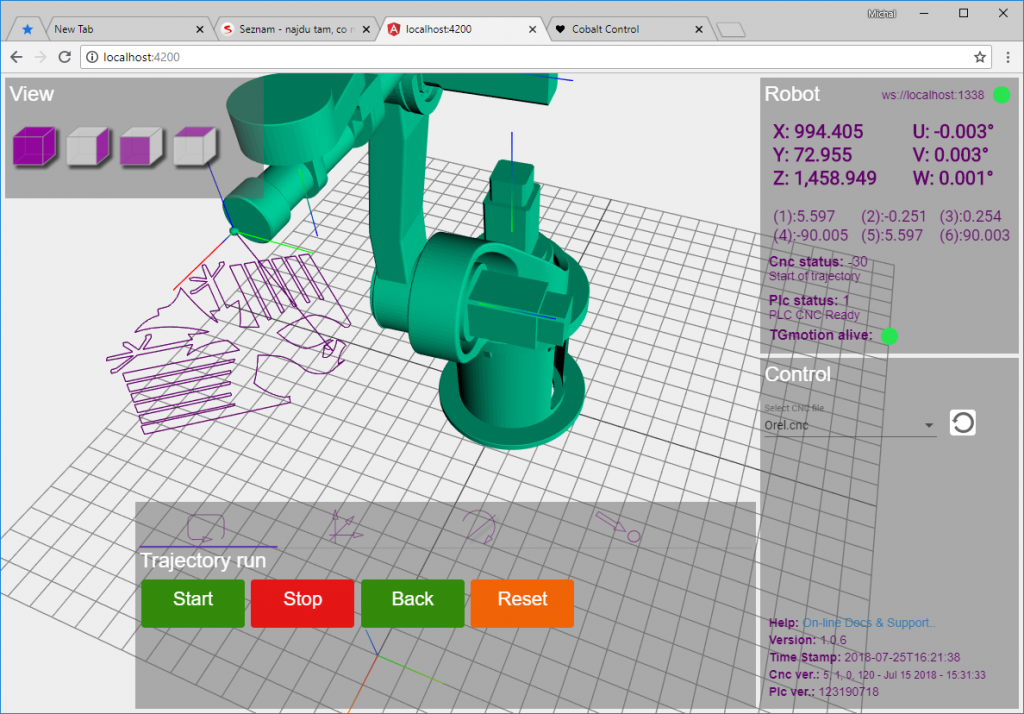

Within your browser you open virtual environment of industrial robot where you can see real state of machine. 3D model of virtual robot controls real machine. You can can simulate and closely analyse any robot operation e.g. you can load G-code file and robot executes this trajectory.

You have many modes of manual movement like cartesian moves, cylindrical moves, special programming of orientation chain and also point to point robot movements.

Industry 4.0 ready

Robot control server includes JSON API interface accessible via local network or Internet. You can access your robot from any devices and customer accounts.

Cloud modules perform high level tasks regarding planning and synchronizing of more robot units. Data analytics helps at optimization of robot work cycles and increasing of performance.